The Future of Additive Manufacturing: MTM Recognition Employs Rose State Graduates Published July 24, 2018

To many, 3D printing is something of the future. However, 3D printing has been around since 1983, bridging the gap between science and art. Additive manufacturing (AM), the overarching field to 3D printing, serves as the foundation of digital fabrication with seemingly endless creative opportunities.

Additive manufacturing is a growing industry worldwide, and Rose State College is at the forefront of college experiences in the field. Rose exposes students to this innovative new field in multiple ways, including offering Engineering and Science curriculum that focuses on additive and subtractive technologies, as well as Rose State’s Business and Information Technology (BIT) Digital Prototyping Lab. Businesses such as Oklahoma’s own MTM Recognition, formerly known as Midwest Trophy, hire Rose State graduates with BIT Lab experience.

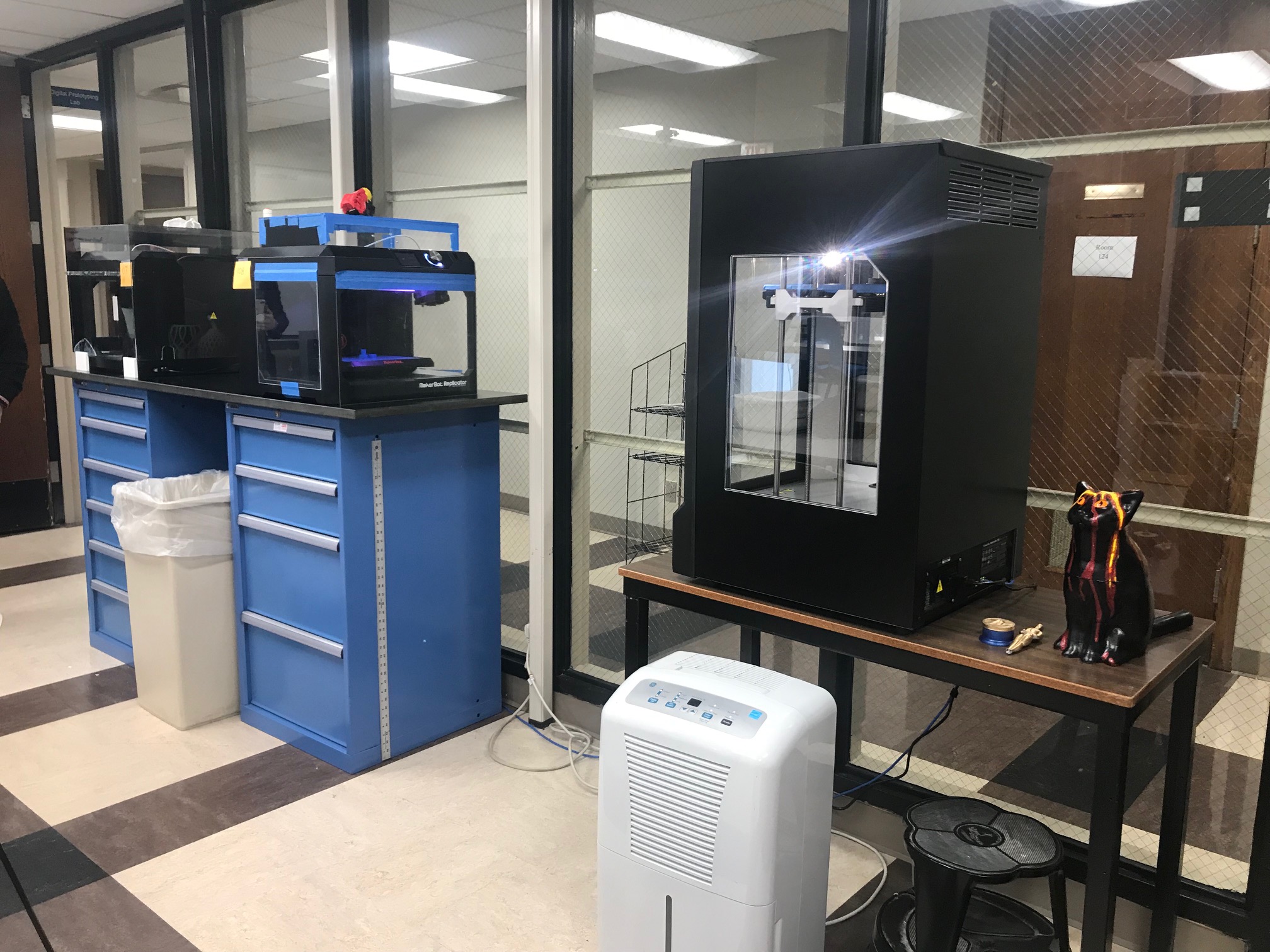

The Digital Prototyping Lab at Rose State

From understanding additive manufacturing software to designing unique 3D printed creations and beyond, the BIT Digital Prototyping Lab at Rose State teaches students the ins and outs of additive manufacturing.

“We teach our students everything they need to know from the ground up,” Terry Byers, professor and director of the BIT Digital Prototyping Lab, says. “We start them with software and pre-designed projects, and then they end up designing their own projects and printing them out.”

The facility boasts several Makerbot 3D printers, the 107, 108, and Z18. “We bought our first printer in 2009, which prints using ADS plastic,” Byers says. “The newer Makerbots print with a PLA plastic that’s actually corn-based.”

The facility has made a home for itself in Rose State curriculum. “The BIT Digital Prototyping Lab was not initially used in academics,” Byers says. “We started the program last October, and that’s the best thing we’ve ever done. When we started teaching, we had students come in and say, ‘What can I download and print?’ We’ve had 68 students in the past three semesters, and now we’re getting the students who say, ‘What can I design?’ Now, we have the students who will carry additive manufacturing forward in the future.”

Students begin the course by studying the software and maintenance of additive manufacturing. “That’s what their potential employers are looking for, not only do you know how to take an object, 3D print it, and modify it so it prints out well, but do you know how to maintain the equipment,” Byers adds.

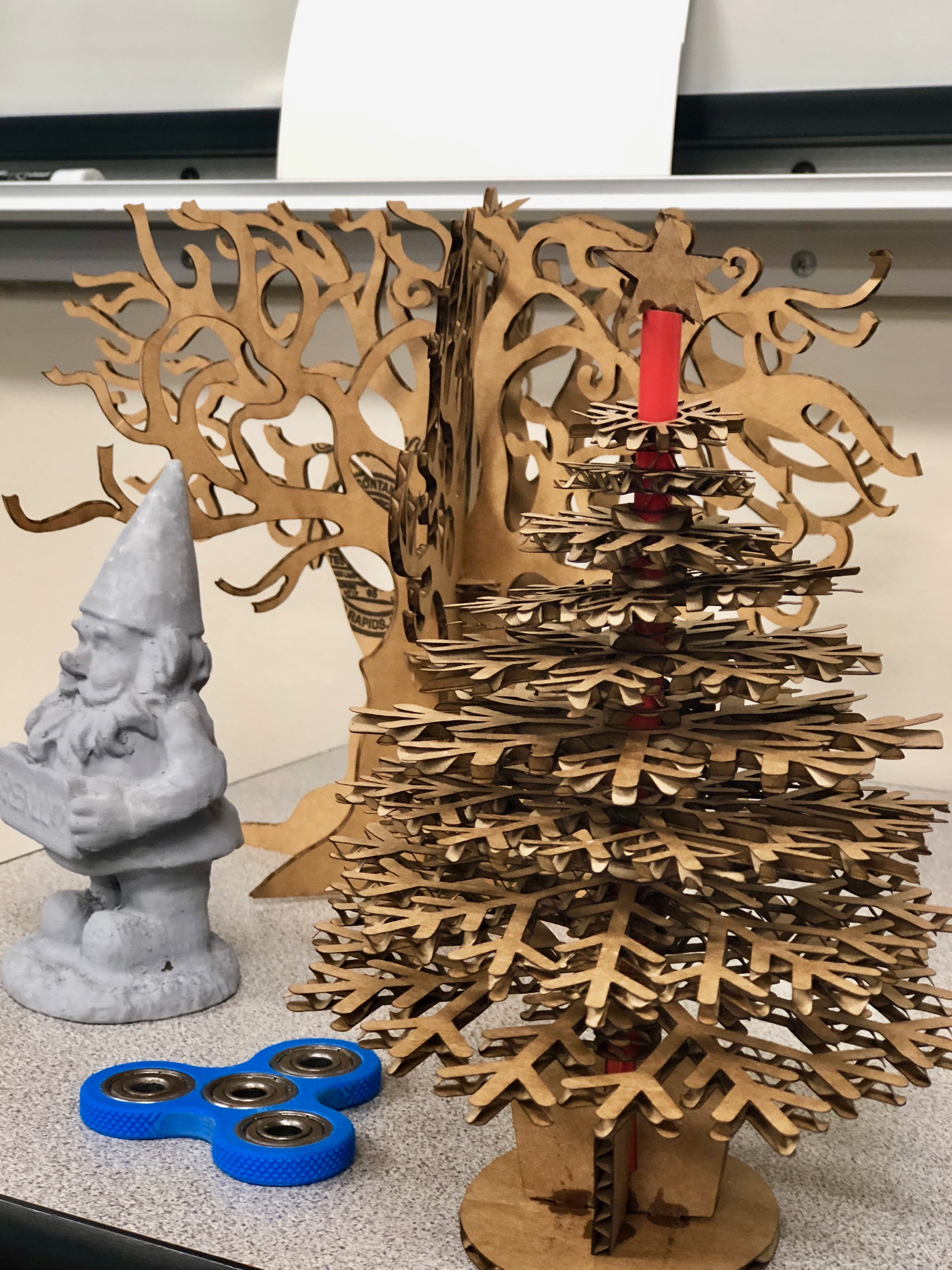

Next, they learn how to operate and maintain the laser printer. “We have them take a 2D drawing and teach them how to make it in 3D,” Byers says. Students can cut designs out of cardboard and piece them together to create a multidimensional creation, such as a Christmas tree.

In subsequent courses, students have the ability to design and print 3D creations. Students have created a variety of 3D products. One class created a prosthetic hand for a woman in Kenya. Other classes have printed a replica of a wrench used on the International Space Station. “NASA couldn’t send a spaceship up to replace the wrench,” Byers says. “Instead, NASA emailed them the file for the wrench and they printed it out. We asked for the file, and they sent us the same email.”

The BIT Digital Prototyping Lab at Rose State is unique because courses are offered to teach students and faculty how to use the equipment. “We focus on our students,” Byers says. “A lot of other campuses have what they call a ‘Maker Space’ where students come in and no one teaches them what to do. They have to learn on their own. We let our students do that, but we also teach them.”

“Advanced manufacturing includes both additive and subtractive technologies, and the Design and Prototype Center provides students with the ability to design components using various software tools,” says Dr. Wayne Jones, Dean of the Engineering and Science Division. “The intent of the BIT and Engineering and Science programs are to prepare engineers and technicians to produce critical components that are used in various industries, such as aerospace, energy and agriculture. This is why proper education on additive manufacturing is so key.”

Terry Byers and BIT Digital Prototyping Lab Coordinator Kimberly Schriewer know firsthand the importance of proper additive manufacturing education. Schriewer was one of the first Prototyping Lab students at Rose State College, and Byers studied additive manufacturing at Lorraine Community College. This knowledge and experience gives them valuable insight into the needs of the workforce—allowing them to properly prepare students for obtaining a career after graduation.

Sending Graduates into the Workforce

Nine Rose State alumni have been employed at MTM Recognition following graduation. Two alums were referred to MTM within the first semester of BIT Lab courses. One was even awarded the MTM 2015 Newcomer of the Year award.

“Both are currently in our Emerging Talent program, which seeks to expose them to in-house research and problem-solving projects as training for potential, future leadership roles,” HR administrator at MTM, Kathy Hudgins says. “This is a definite win/win partnership, aligning students with jobs in their line of study and providing us with quality employees who can ‘hit the ground running.’ ”

“We have a very good relationship with MTM, and they do a good job of interviewing and testing our students—choosing to hire the best ones,” Byers says.

MTM Recognition is the largest and most diverse awards manufacturer in the country. In addition to creating memorabilia, fine jewelry, and awards, MTM creates and implements programs celebrating achievement, rewarding performance, and honoring service, while branding and reinforcing company image. Spanning 20 acres in Del City, OK, MTM Headquarters is home to some of the country’s most notable awards, including the Heisman Trophy.

Rose State and MTM work hand-in-hand to educate students on the additive manufacturing workforce. Students recently toured MTM’s facility during a Manufacturing Day open house to gain firsthand insight into the skills required in various areas of awards production, and the technology involved in the manufacturing process. "We really enjoyed hosting Rose State students and educators and were very impressed with their level of interest and the questions that they asked along the tour," MTM director of communications, Dona Lamprecht says.

MTM recognizes the unique opportunity Rose State’s BIT Digital Prototyping Lab provides students.

“The key is the BIT Lab at Rose State,” Rick Bewley, of MTM’s Research and Development team, says. “That speaks to and trains on everything we do here. People we’ve had from Rose State that end up working here aren’t always employed as 3D modelers, but they understand the digital interface and equipment we have. They are already up-to-speed on setting up parameters for running products from decoration and engraving to laser printing.”

The BIT Lab at Rose State has broken the mold for providing students from a variety of backgrounds with unique experience and insight into a blossoming industry. “We start students off by telling them, ‘Anything you can think of, you can create,’” Byers says. The students and faculty involved in BIT Lab courses take that lesson to heart, expanding the workforce in corporations such as MTM Recognition.

It doesn’t stop there. In January of 2019, Rose State is planning to offer a Digital Technician Certificate to be obtained through education with the BIT Digital Prototyping Lab. If you are interested in obtaining a Digital Technician certificate in the field of Additive Manufacturing, we encourage you to contact us today. For more information about campus resources at Rose State, download our Campus Resource Guide.